Why Choose Dorf Ketal?

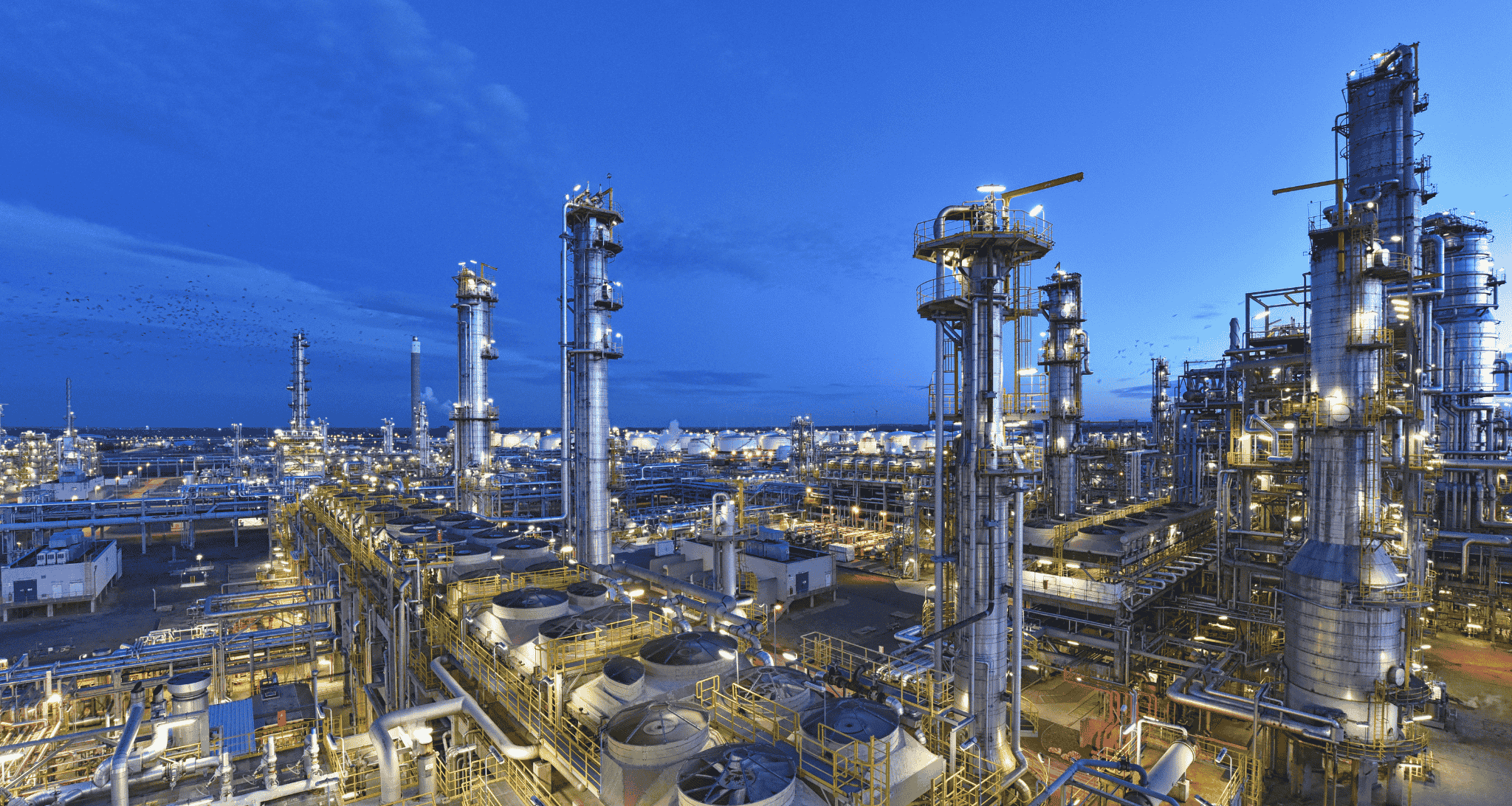

Major Producer Process Chemicals

Established in 1992, Dorf Ketal Chemicals has emerged as a major producer in the development, commercialization, and application of specialty engineered chemistries for the hydrocarbon and industrial specialty chemical sectors. With a commitment to innovation and excellence, we provide solutions that address some of the most technically challenging and mission-critical applications in the world’s largest refineries and petrochemical plants.

Our state-of-the-art technologies are designed to meet the evolving demands of the industry, offering innovative chemistries and tailored services that are both responsive and practical. From our notable market presence in India, Brazil, and Southeast Asia to our expanding global footprint, Dorf Ketal continues to grow and deliver value across key regions.

As a forward-thinking company, we bring fresh perspectives and cutting-edge solutions, helping our clients optimize their operations while ensuring long-term success. If you are looking to enhance your supply chain with a partner that prioritizes innovation and operational excellence, Dorf Ketal is the partner you have been looking for.

Our Focus

Sustainable Chemical Solutions

Our focus is on sustainability, offering chemicals that ensure asset integrity, flow assurance, fuel efficiency, safe handling, and water consumption reduction.

1,900+

Employees

550+

Patents

16

Manufacturing Facilities

Hydrocarbon Specialty Chemicals

From upstream to downstream, our hydrocarbon specialty chemicals provide comprehensive coverage—from well to wheels.

Industrial Specialty Chemicals

Engineered to meet your needs, our industrial specialty chemicals support every stage of your operations.

Join Our Team of Innovators

Careers At Dorf Ketal

Awards & Memberships

2017

Award for Social Responsibility by Indian Chemical Council

2018

Best Use of CSR Practices in Specialty Chemicals Segment by CMO Asia

2018

Best CSR Impact Initiative by National Awards for Excellence in CSR & Sustainability – India

2018

Award for Excellence in Management of Health and Safety by the Indian Chemical Council

2018

Appreciation Letter for Innovative Technologies and Superior Performance from Petronas

2018

Certificate of appreciation in recognition of achievement in Occupational, Safety and Health by the National Safety Council of India for the years

2019

Clarivate Analytics India Innovation Awards 2019 by Clarivate Analytics

2019

Best Corporate Social Responsibility Practices by ET Now’s CSR Leadership Awards

2020

Certificate of appreciation in recognition of achievement in Occupational, Safety and Health by the National Safety Council of India

2022

Five-Star Grade and Sword of Honour from the British Safety Council

2022

EcoVadis Sustainability Rating Gold

2017

Award for Social Responsibility by Indian Chemical Council

2018

Best Use of CSR Practices in Specialty Chemicals Segment by CMO Asia

2018

Best CSR Impact Initiative by National Awards for Excellence in CSR & Sustainability – India

2018

Award for Excellence in Management of Health and Safety by the Indian Chemical Council

2018

Appreciation Letter for Innovative Technologies and Superior Performance from Petronas

2018

Certificate of appreciation in recognition of achievement in Occupational, Safety and Health by the National Safety Council of India for the years

2019

Clarivate Analytics India Innovation Awards 2019 by Clarivate Analytics

2019

Best Corporate Social Responsibility Practices by ET Now’s CSR Leadership Awards

2020

Certificate of appreciation in recognition of achievement in Occupational, Safety and Health by the National Safety Council of India

2022

Five-Star Grade and Sword of Honour from the British Safety Council

2022

EcoVadis Sustainability Rating Gold