Product Innovation Delivering Results You Can Measure

Our big ideas have come from one source: You, our customers. You’ve motivated us to work hard to find winning solutions for your unique challenges and you’ve trusted our industry-leading R&D to get the job done.

You manage assets worth hundreds of millions of dollars – or more – and we realize you don’t have the time or money to waste on solutions that don’t work. With Industry Leading expertise and a commitment to both basic and applied research, Dorf Ketal moves quickly and decisively to provide chemical process solutions that deliver superior value at the lowest cost-in-use.

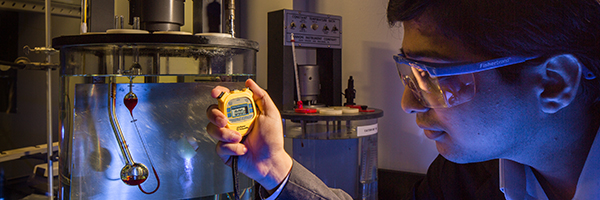

Dorf Ketal is the epitome of a young company that has discovered game changing technologies. Our research, pilot plants, and modelling capabilities together with the people behind them are dedicated to getting you solutions for today and tomorrow.

When you partner with us, you will experience a company that is;

- Much faster to respond to your needs

- Extremely innovative in finding and commercializing technologies that work.

- Easy for customers to do business with.

That’s why our products and services are unmatched in the industry.

Our Measure of Success: Your improved operations

The Dorf Ketal research and development team based in Taloja, India works with a global laboratory network to innovate and commercialize solutions to solve your most demanding problems. You can find our innovative process technology across the globe and in some of the largest production facilities in the world.

Our customer centric focus drives innovation which includes these process technologies:

- Emulsion Breakers for Opportunity Crudes –provide multiple functionality to improve desalting performance and allow refiners to increase the amount of cost advantaged crudes they process.

- Reactive Adjunct Desalting Chemistry is a new fourth category of adjunct desalter chemistry. This new chemistry increases the speed of emulsion breaking which improves rag layer control and results in higher desalter efficiency without capital investment.

- Amine Removal Agent –new non-acid chemistry sequesters amine and reduces corrosion risk in Crude Column Overhead by breaking the amine cycle without the safety risks of using acid.

- Crude Oil Metals Removal Technologies improve Desalting – new organic acid and non-acid solutions for sweet and sour crudes remove metals and eliminate stable emulsions of water insoluble solids, and prevent downstream issues in the overheads and catalyst systems.

- TANSCIENT™ : High Temperature Corrosion Inhibition (HTCI) offers a cost-effective alternative to metallurgical upgrades or use of phosphate esters, allowing refiners to consider the use of lower cost high acid crudes.

- MAXSCAV™ Hydrogen Sulfide Scavengers: New technology for improving performance of non-regenerative H2S scavenging chemistries including MEA-triazine, MMA-triazine, glyoxal, zinc-based, iron-based, and others.

- COMPASS™ - predictive monitoring system that maximizes performance and reliability of Cracked Gas Compressor systems in ethylene plants

- Innovative chemical solutions and proactive predictive modeling systems that drive reliability and yield enhancement across key units of operation in the ethylene, styrene and butadiene manufacturing processes. Especially those move to more challenging feedstocks.

- ACtify® technologies instantly lower equilibrium levels of polymer in styrene monomer distillation systems.

- Tailored Antifoulants for Visbreaker Units – simulation tools applied to customize fouling control chemistries to address specific feed and deposit components and maximize the production of more valuable liquid yields.

- TYZOR® ACtivate™ - PET catalyst for bottle, film and polyester fiber reduces melt phase cost-in-use

The best ideas come from a combination of inspiration and perspiration. Thank you for motivating us to work hard to deliver new solutions that help you improve your operations and save you more money.

Check out new chemistries for your operations

Contact Us